HOW TO BENEFIT FROM OUR SERVICE

CAST IRON WELDING? OUR PATENTED METALOCK PROCESS

Cast iron cannot be welded. But we have good news for you. Sustainable repair of cast iron is possible if you rely on our specialised Metalock process. Thanks to the specialized incorporation of special "Metalock bars", the Metalock process enables safe and effective repair of cast iron in a cold process – without welding, without heat distortion and, in most cases, without dismantling.

REQUEST INFO-SET NOW

We would be happy to send you our detailed brochures on the subject of cast iron repairs with the Metalock process as well as further information on Metalock as a PDF free of charge. Simply enter your e-mail address in the field below and you will immediately receive an e-mail with the download links.

FIELDS OF APPLICATION

CAST IRON REPAIRS – SUITABLE FOR ALL INDUSTRIES

-

BUILDINGS

Cast iron components are not only found in machinery and plant engineering, but also in architecture. Stairs, bridges, railings and supporting structures, especially in historical buildings, are typical examples made of cast iron.

Here, too, we often use the Metalock method to repair and touch up different types of cast iron such as cast aluminium, cast grey iron and cast steel. As a cold process, the procedure is particularly suitable for challenging components because, unlike welding, there is no heat distortion. In addition, the gentle process helps to preserve the original condition for as long as possible, especially in listed buildings.

-

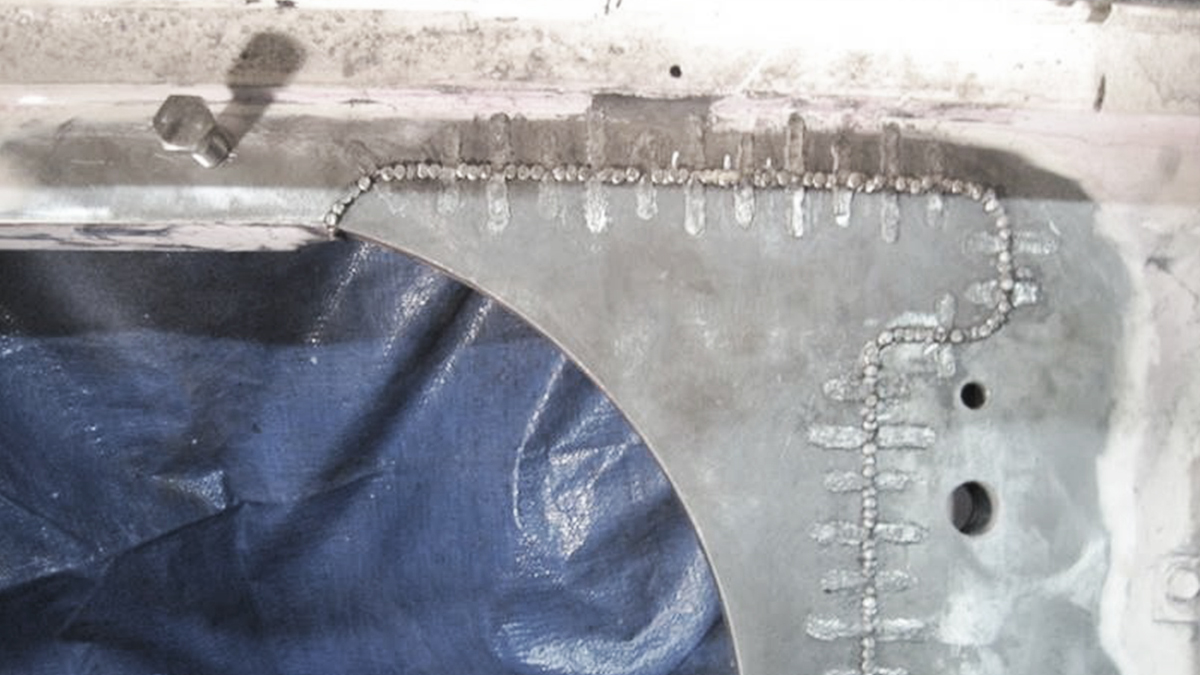

SHIP ENGINE BLOCKS

Time is a critical factor, especially in shipping. That's why we put an end to long downtimes with the Metalock process. If an engine block has a crack or fracture in the cast iron, for example, our specialists can be on site within 24 hours and carry out the cast iron repair without dismantling at sea or on land.

In an operation of this kind, we first check the fracture in the cast iron and work out the damaged area. We then manufacture a new fitting, which is inserted using the Metalock method. This patented method is recognised by all classification societies.

-

GEAR WHEELS

Wind turbines are now superlative structures. Huge gear wheels interlock and transmit the wind power from the rotor blades to the generator. As soon as a tooth segment breaks, the transmission is interrupted and the wind turbine comes to a standstill. Now the cast iron element has to be repaired as quickly as possible.

Thanks to the Metalock process, it is possible to machine out the defective tooth and replace it with a new tooth segment without welding the cast iron. In addition to the wind energy sector, we also machine and repair gears from a size of 1,000 mm in numerous other industries using the Metalock process.

-

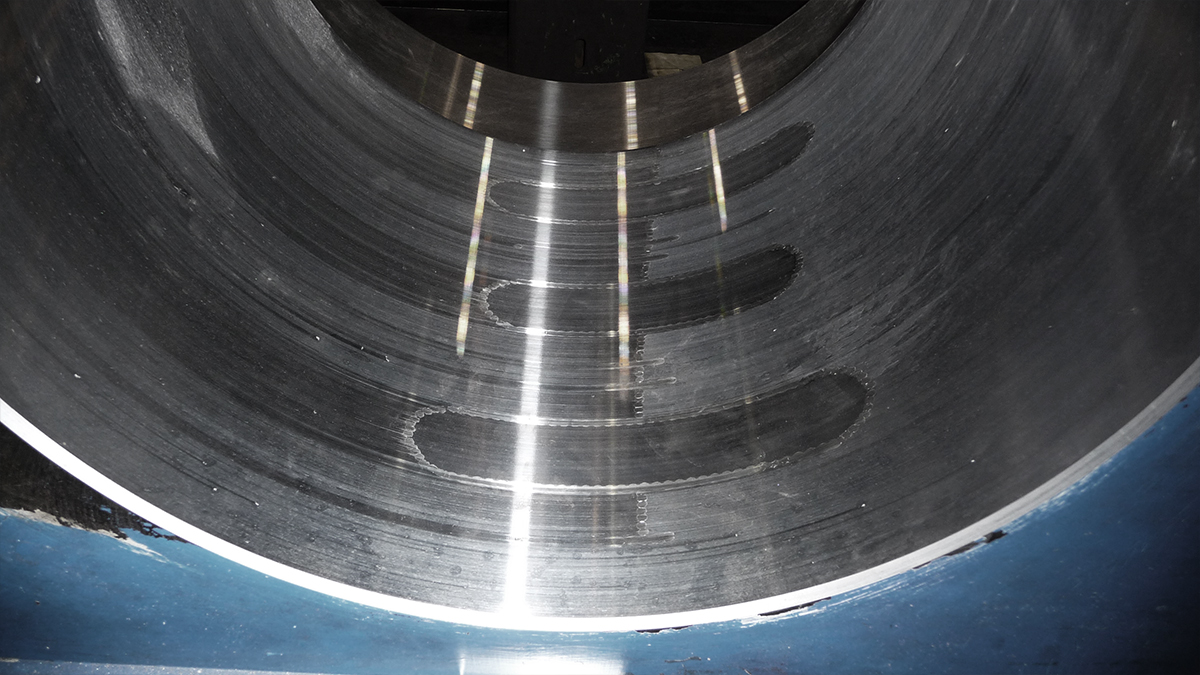

INDUSTRIAL MACHINERY

With our Metalock process, we dispense with the welding of cast iron parts, which brings numerous advantages, especially in sensitive working environments. We are therefore able to repair all types of cast iron machine stands and housings in all industrial fields of application, such as press stands or gearbox housings.

In order to meet the respective industry-specific requirements of the order quickly and reliably, we have a large number of transportable special tools and special machines. This means that we have a suitable solution ready for every customer application and can repair the damaged cast iron element within a short time.

-

BUILDINGS

BUILDINGS

Cast iron components are not only found in machinery and plant engineering, but also in architecture. Stairs, bridges, railings and supporting structures, especially in historical buildings, are typical examples made of cast iron.

Here, too, we often use the Metalock method to repair and touch up different types of cast iron such as cast aluminium, cast grey iron and cast steel. As a cold process, the procedure is particularly suitable for challenging components because, unlike welding, there is no heat distortion. In addition, the gentle process helps to preserve the original condition for as long as possible, especially in listed buildings.

-

SHIP ENGINE BLOCKS

SHIP ENGINE BLOCKS

Time is a critical factor, especially in shipping. That's why we put an end to long downtimes with the Metalock process. If an engine block has a crack or fracture in the cast iron, for example, our specialists can be on site within 24 hours and carry out the cast iron repair without dismantling at sea or on land.

In an operation of this kind, we first check the fracture in the cast iron and work out the damaged area. We then manufacture a new fitting, which is inserted using the Metalock method. This patented method is recognised by all classification societies.

-

GEAR WHEELS

GEAR WHEELS

Wind turbines are now superlative structures. Huge gear wheels interlock and transmit the wind power from the rotor blades to the generator. As soon as a tooth segment breaks, the transmission is interrupted and the wind turbine comes to a standstill. Now the cast iron element has to be repaired as quickly as possible.

Thanks to the Metalock process, it is possible to machine out the defective tooth and replace it with a new tooth segment without welding the cast iron. In addition to the wind energy sector, we also machine and repair gears from a size of 1,000 mm in numerous other industries using the Metalock process.

-

INDUSTRIAL MACHINERY

INDUSTRIAL MACHINERY

With our Metalock process, we dispense with the welding of cast iron parts, which brings numerous advantages, especially in sensitive working environments. We are therefore able to repair all types of cast iron machine stands and housings in all industrial fields of application, such as press stands or gearbox housings.

In order to meet the respective industry-specific requirements of the order quickly and reliably, we have a large number of transportable special tools and special machines. This means that we have a suitable solution ready for every customer application and can repair the damaged cast iron element within a short time.

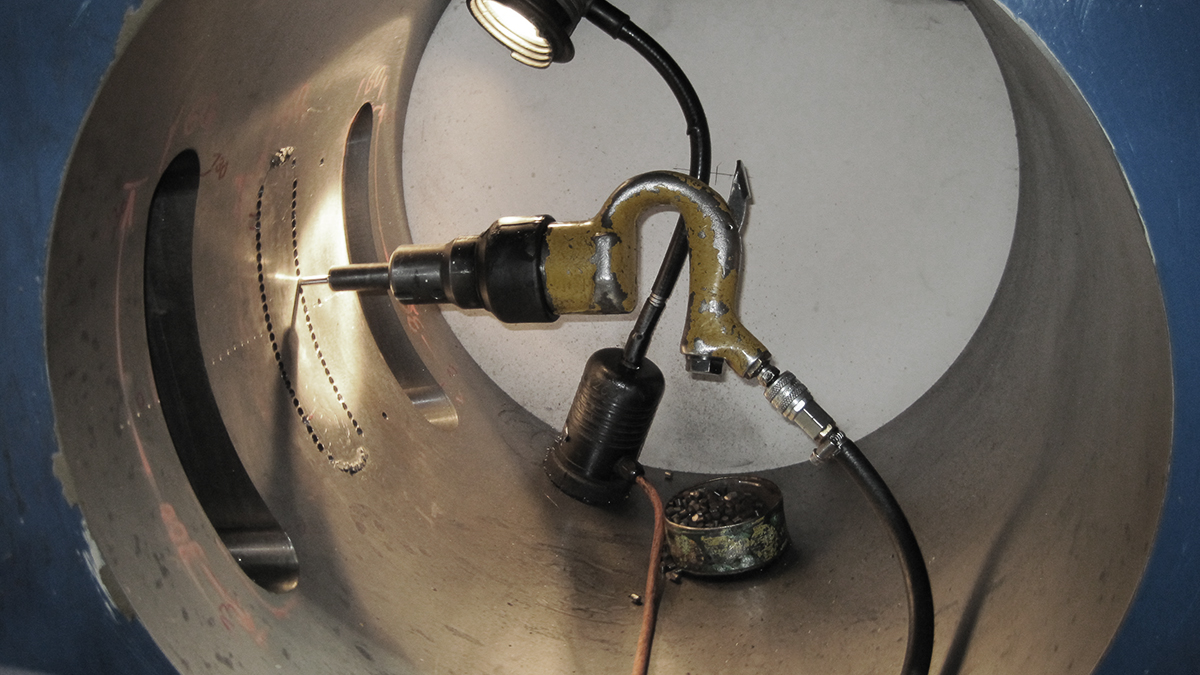

HOW DOES THE METALOCK PROCESS WORK?

COLD REPAIR PROCESS FOR CRACKED OR BROKEN CASTINGS

The Metalock method is a simple but very effective method to repair fractures and cracks of cast iron components without welding. This "locking method" is recognised worldwide and registered in the Lloyd Register for the repair of certain components under certificate no. MNDE/REP/0017/06.

THE FOUR ESSENTIAL REPAIR STEPS ARE:

YOUR BENEFITS

CAST IRON REPAIRS WITHOUT WELDING

Time

Savings

No

Disassembly

Gas/Oil &

Pressure-tight

No Heat

Distortion

Cost

Savings

Certified

Procedure

CONTACT US NOW

HOW TO USE THE METALOCK PROCEDURE IN YOUR FIELD

We will gladly inform you in advance or help you immediately in case of an emergency. Please do not hesitate to contact us. You can reach us via contact form or at metalockrepair(at)metalock.de. In urgent cases, please use our 24h-Emergency Help Number.

ABOUT METALOCK ENGINEERING GERMANY

RELIABLE REPAIRS SINCE 1952

As part of the MIDROC Metalock Group, Metalock Engineering Germany benefits from the international group's many years of extensive experience. The company's technical know-how is in every single processing step of the Metalock process, opening up new possibilities for the repair of cast iron.

OUR SERVICES

OUR LOCATIONS IN GERMANY